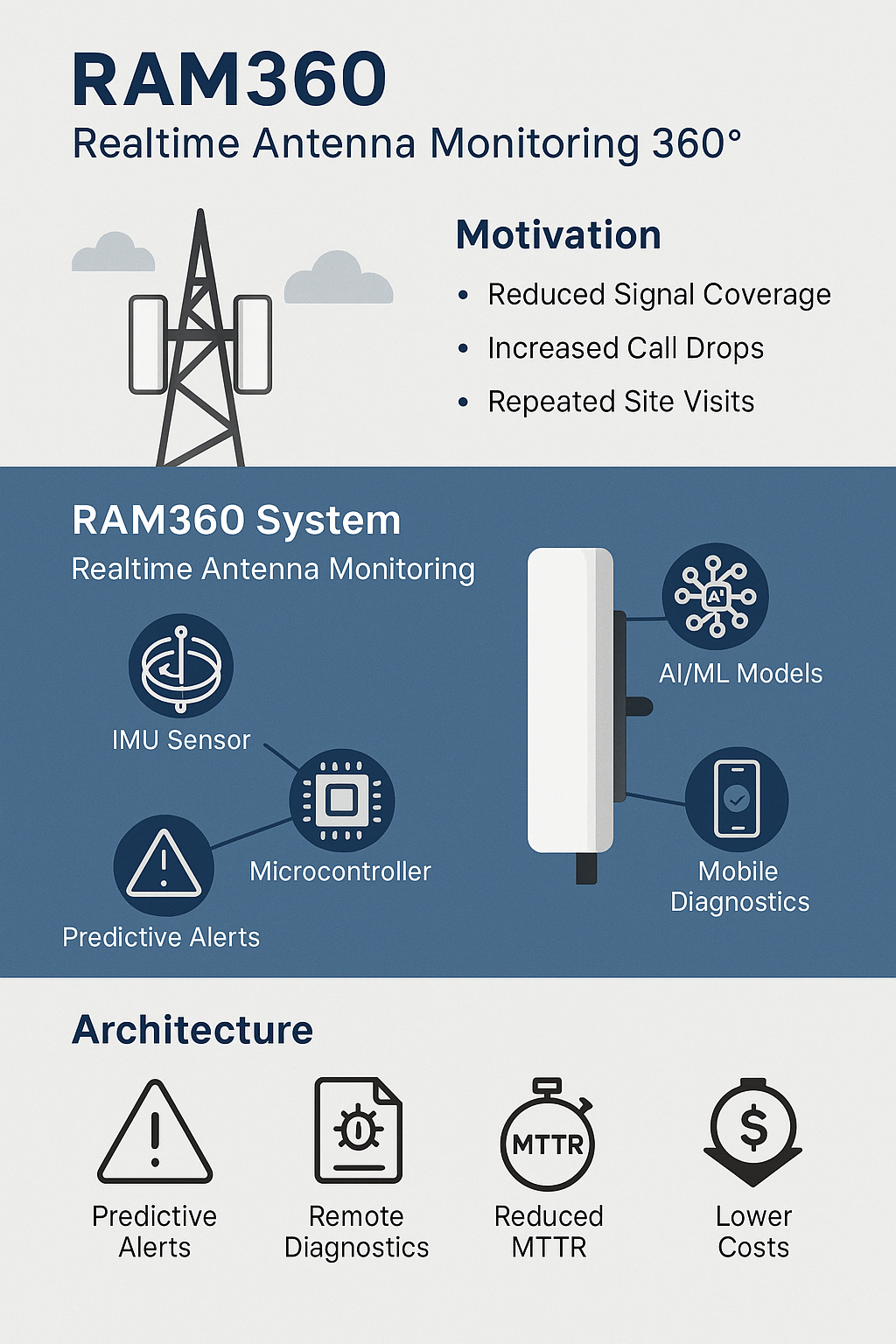

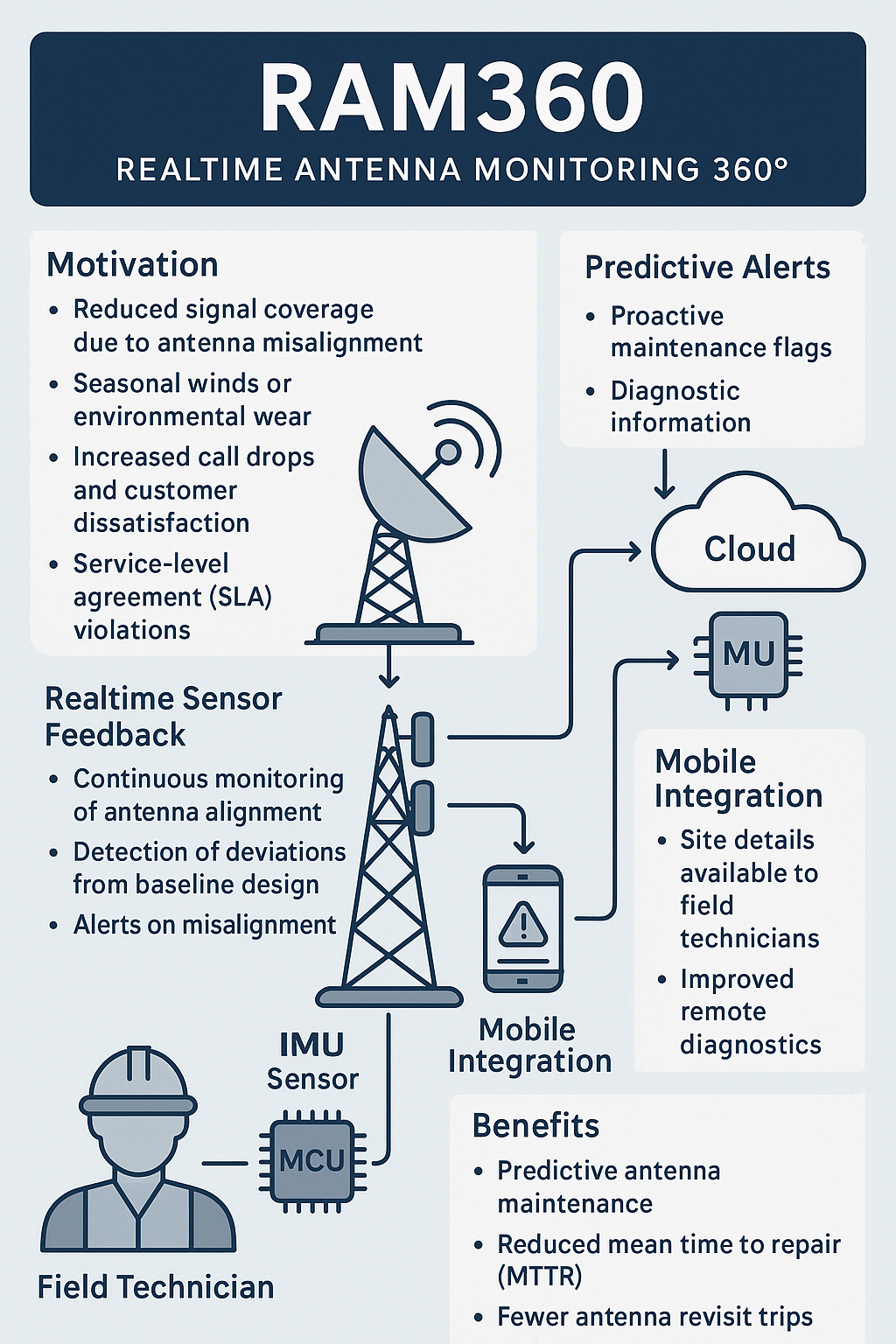

In the high-stakes world of telecommunications infrastructure, antenna alignment is not just a technical detail—it is a foundational requirement for ensuring optimal Quality of Service (QoS), regulatory compliance, and cost efficiency. Enter RAM360, an innovative Realtime Antenna Monitoring system designed to mitigate tower misalignment challenges and transform maintenance workflows through predictive analytics and sensor intelligence.

Why RAM360 Matters in Telecom Infrastructure

Cellular network operators are under relentless pressure to deliver uninterrupted voice and data services. However, antenna misalignment, caused by seasonal winds or environmental degradation, leads to:

- Reduced Signal Coverage

- Increased Call Drops

- Customer Dissatisfaction

- Violation of Service-Level Agreements (SLAs)

According to field data, nearly 50% of telecom tower sites require revisits to fix antenna misalignments. Each site visit involves logistical overhead, labor costs, and elevated Mean-Time-To-Repair (MTTR), which directly affects carrier margins and performance benchmarks.

RAM360: What Is It?

RAM360 is a smart sensor-based platform mounted on telecom towers to enable 360-degree real-time monitoring of antenna positioning and alignment. Unlike traditional post-fault diagnosis tools, RAM360 provides continuous data telemetry, alerting field engineers and network operations centers (NOCs) the moment anomalies arise.

Key Features

| Feature | Description |

|---|---|

| Realtime Sensor Feedback | Continuously monitors physical orientation (azimuth, tilt, roll) of antennas |

| Predictive Alerts | AI/ML models detect deviations from baseline design and trigger proactive maintenance flags |

| Remote Diagnostics | Site crews can access detailed misalignment diagnostics before arriving at the location |

| MTTR Optimization | Drastically reduces downtime by eliminating multiple site visits and guesswork |

Technical Architecture of RAM360

A typical RAM360 deployment includes:

- High-Precision IMU Sensor (Inertial Measurement Unit):

- Captures real-time spatial orientation of antenna panels.

- Resolution: Sub-degree accuracy for roll, pitch, and yaw.

- Edge Microcontroller Unit (MCU):

- Locally processes sensor signals.

- Ensures minimal latency and local anomaly detection.

- Communicates with central cloud via secure MQTT/HTTPS.

- Cloud Analytics Layer:

- Aggregates data from multiple towers.

- Employs pattern recognition models for predictive failure analytics.

- Dashboards for engineers and SLA managers.

- Mobile Integration:

- Field technicians can receive real-time site diagnostics and correction instructions directly on mobile devices.

Impact on Operational Metrics

RAM360 doesn’t just detect problems—it transforms workflows:

| Metric | Before RAM360 | After RAM360 |

|---|---|---|

| Antenna Revisit Rate | ~45% | <10% |

| MTTR | 48–72 hours | <24 hours |

| Site Labor Cost | High | Reduced by 35–50% |

| SLA Violation Risk | Moderate to High | Significantly lowered |

Strategic Advantages for Telecom Operators

- CapEx Protection: Antenna systems represent significant capital investments. RAM360 ensures their alignment and longevity.

- Customer Experience: Improved QoS through stable RF coverage.

- Regulatory Compliance: Adherence to national signal strength and outage prevention mandates.

- Environmental Resilience: Detects climate-induced physical shifts, enabling preventive action.

What’s Next: Integration with Digital Twin and 5G

Future iterations of RAM360 may integrate with Digital Twin Platforms, enabling simulation of entire cell-site behavior under various alignment scenarios. Moreover, with 5G’s sensitivity to antenna orientation, RAM360 becomes even more critical.

Envisioned Upgrades:

- Real-time 3D antenna orientation visualizations.

- AI-generated tilt-correction suggestions.

- Drone-assisted hardware checks.

Final Thoughts

RAM360 offers a practical, data-driven solution to one of telecom’s most expensive and recurring problems. By turning antennas into self-monitoring entities, it redefines how telcos maintain infrastructure and respond to environmental challenges. It’s not just a monitoring solution—it’s a step toward self-healing networks.

RAM360 Unveiled: A Technical Deep Dive into Realtime Antenna Monitoring for Intelligent Telco Infrastructure As the telecom industry scales to meet the growing demands of 5G and beyond, the emphasis on network resilience, precision, and automation is more critical than ever. RAM360—a Realtime Antenna Monitoring system—ushers in a new paradigm by leveraging edge computing, IoT, and AI analytics to provide 24/7 situational awareness of antenna orientation and health.

In this technical deep dive, we explore how RAM360 works, its critical subcomponents, the role of sensor fusion, and future directions involving autonomous remediation and digital twin integration.

SYSTEM OVERVIEW: Anatomy of RAM360

RAM360 is a distributed sensor-intelligence system that provides live monitoring, early-warning alerts, and diagnostic telemetry of telecom antennas. The architecture spans from the tower-edge to the cloud core.

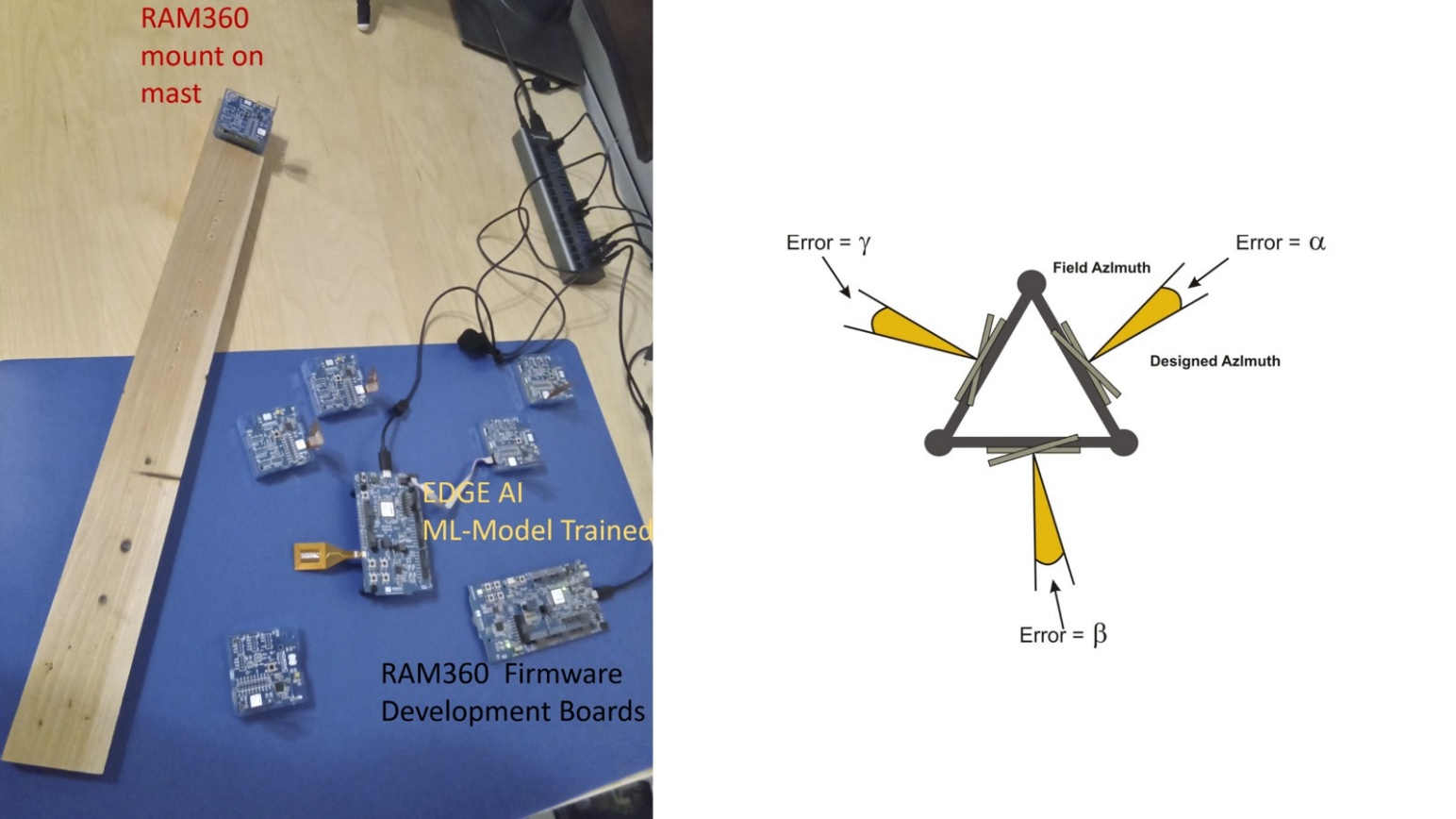

1. Sensor Subsystem: Inertial Sensing and Fusion

- Primary Sensors: Triaxial accelerometer, gyroscope, magnetometer (IMU array)

- Fusion Algorithm: Extended Kalman Filter (EKF) or Madgwick Filter for drift-free orientation estimation

- Key Measurements:

- Azimuth (rotation on vertical axis)

- Elevation/Tilt (pitch)

- Roll (rotation around antenna axis)

- Sampling Rate: Typically 10–100 Hz with dynamic oversampling during storm conditions

2. Edge Computing Node (MCU/SoC)

- Runs embedded firmware for real-time signal processing

- Implements vibration damping logic and transient detection (e.g., gust resilience)

- Calculates local deviation thresholds

- Sends compressed event packets upstream over MQTT/CoAP

3. Network Communication Layer

- Uplink Protocols: MQTT over TLS, CoAP, or WebSocket with optional LoRaWAN fallback

- Redundancy: Dual SIM/Radio fallback with SD-WAN failover (if integrated at multi-antenna hub level)

- Payloads: CBOR/JSON encoded telemetry with LWM2M or custom schemas

CLOUD PLATFORM: AI-DRIVEN ANALYTICS AND AUTOMATION

Key Modules:

Anomaly Detection Engine

- Pretrained using LSTM-based time-series models

- Learns baseline orientation behavior per antenna under normal conditions

- Detects anomalies in:

- Gradual drifts (due to aging)

- Sudden shifts (e.g., wind storms or mechanical impact)

Drift Compensation Model

- Uses historical baseline correction and tower-specific environmental modifiers (e.g., wind load data from NOAA or custom models)

- Flags only meaningful shifts, ignoring thermal or seasonal tilt microvariations

Prescriptive Diagnostics

- Integrates RF models with current antenna orientation to simulate predicted coverage loss

- Recommends precise angular corrections (e.g., +4.2° azimuth, -1.6° tilt)

- Annotates fault categories: structural, environmental, installation fault

FIELD OPERATIONS: SENSOR-AIDED TECHNICIAN GUIDANCE

RAM360 Mobile App Capabilities:

- Real-time map of site alignment statuses

- Visual overlays of expected vs current beamforming vectors

- Augmented Reality (AR) interface for on-tower alignment instructions

- AI-chat assistant for field queries (e.g., “What caused the last shift at Tower ID A19?”)

Operational Features:

- Remote re-verification post-adjustment using field-mobile linkage

- 3D gyroscopic replay of misalignment events

- Integration with NOC ticketing systems (e.g., ServiceNow, IBM Maximo)

SECURITY & RELIABILITY DESIGN

| Area | Mechanism |

|---|---|

| Device Identity | X.509 certs, TPM-backed device auth |

| Data Privacy | End-to-end AES-256 encryption, TLS 1.3 |

| Firmware Integrity | Secure boot, OTA update signing |

| Uptime | Battery backup, edge caching, offline re-sync |

| Audit Trail | Blockchain-based logs for SLA verification |

TECHNOLOGICAL EXTRAPOLATIONS

1. Digital Twin Integration

- RAM360 feeds into 3D digital twin models of towers

- Simulates the impact of alignment changes on user density clusters

- Enables city-scale RF coverage simulations in real time

2. Autonomous Remediation Robotics

- Future agents (e.g., drone + robotic arm combos) can auto-correct antenna alignment using RAM360 as visual and sensory reference

3. 5G Massive MIMO Alignment Optimization

- In Massive MIMO setups, even minor tilt drifts impact beamforming

- RAM360’s orientation data used to calibrate dynamic beam codes for optimal downlink gain

4. Predictive Failure Chains

- Combines RAM360 output with tower structural health sensors to predict full-stack failures

- Example: Persistent roll drift + anchor bolt stress signals → predictive structural crack alert

BUSINESS VALUE MODEL

| KPI | Baseline | With RAM360 |

|---|---|---|

| Site revisit frequency | ~40–50% annually | <10% |

| MTTR | 2.5 days avg | <1 day |

| Downtime-related penalty | High | Negligible |

| SLA compliance | ~80% | 95–99% |

| OPEX on tower maintenance | Baseline | ↓30–50% |

STRATEGIC IMPLICATIONS FOR TELCOS

- Competitive Edge: Early warning systems increase NPS (Net Promoter Score)

- Sustainability: Reduces truck rolls and fuel emissions from unnecessary revisits

- Scalability: Plug-and-play module easily fits into greenfield or legacy deployments

- Standardization Potential: Candidate for 3GPP, TM Forum, and ETSI monitoring interface models

Conclusion

RAM360 doesn’t just monitor—it predicts, prevents, and prescribes. As 5G demands grow and edge intelligence becomes standard, solutions like RAM360 are essential for scaling operations without scaling costs or complexity. Its modularity and future-ready AI pipeline position it as a critical enabler of intelligent, self-healing telco infrastructure.

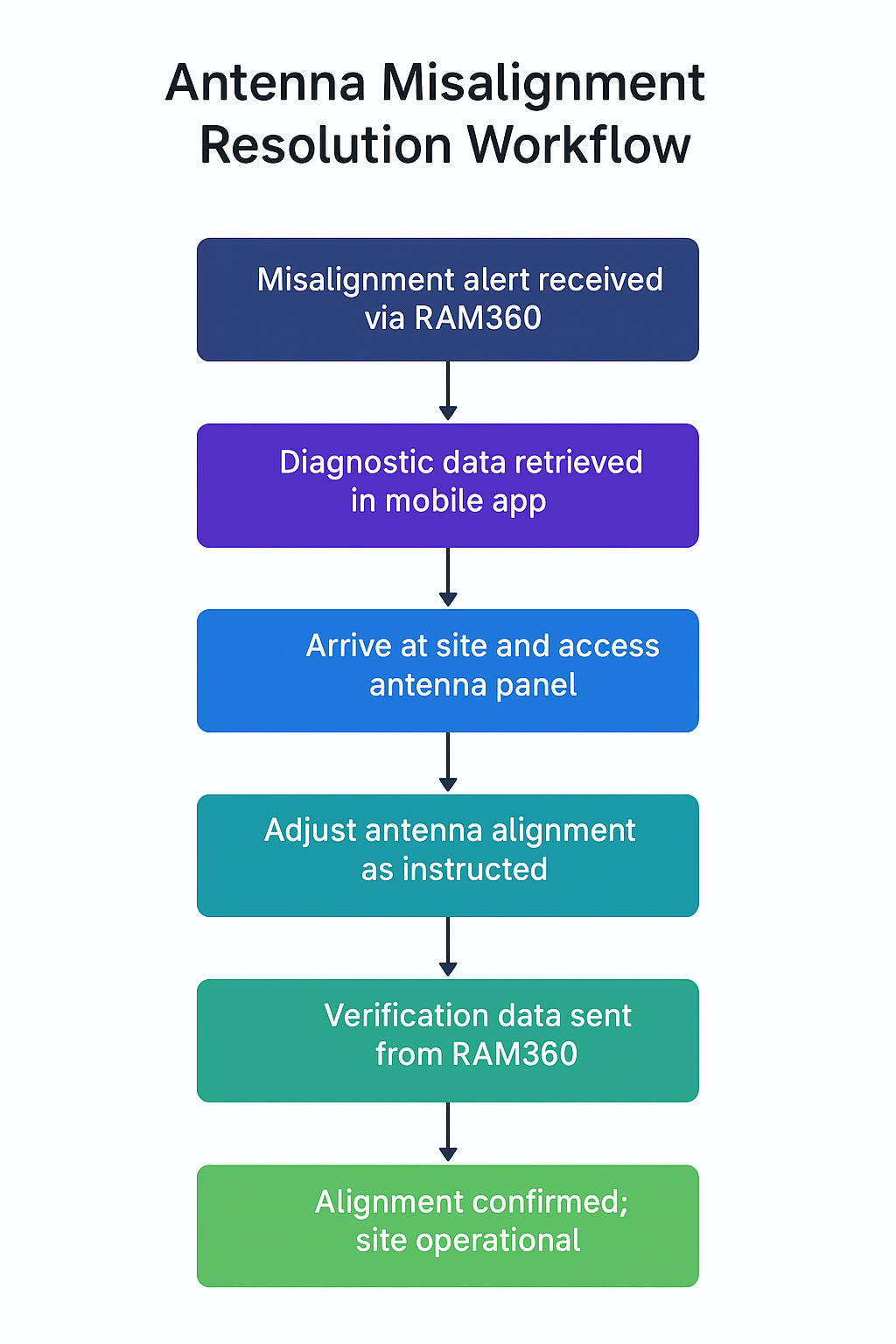

Field Technician Workflow with RAM360

1. Pre-Dispatch Diagnostics via Mobile App

RAM360 empowers the technician before arriving at the site through mobile integration with the cloud dashboard:

| Functionality | Technical Details |

|---|---|

| Misalignment Alert | App receives anomaly alert tagged with antenna ID, tower ID, and timestamp |

| Visualization | 3D model shows current vs intended azimuth, tilt, roll values |

| Correction Guidance | AI-driven instruction set: “Adjust antenna ID#37 azimuth by +3.7°, tilt by -1.2°” |

| Predictive Failure Report | Includes weather logs, past drift history, and SLA breach risk forecast |

Example Prompt:

“Tower T-55 Panel 2 drifted 4.1° clockwise from design alignment. Estimated impact: 12% sector overlap loss.”

2. On-Tower Assisted Alignment

Once on-site, RAM360 offers guided correction:

| Step | Technician Tool | RAM360 Assistance | |||

|---|---|---|---|---|---|

| Climb tower & identify antenna | QR/NFC Tag Scan | Confirms device identity and last known misalignment vector | |||

| Mount mobile device on field rig | Mobile Clamp Interface | Opens dynamic live view overlaying compass + tilt data | |||

| Begin realignment | Torque wrench + angle tool | Real-time data streaming shows live delta from ideal values | |||

| Lock & verify | App captures snapshot | Confirms lock-in within error tolerance (e.g., ±0.3°) | |||

| Submit correction log | Digitally signed report | Includes corrected orientation, GPS timestamp, and technician ID |

Live Feedback Loop:

The app shows “✔ Alignment Optimal” once deviation is under configured limits.

3. Post-Correction Audit and Reporting

After adjustment:

| Feature | Description |

|---|---|

| Re-telemetry | RAM360 sensors immediately report corrected posture to cloud |

| Automated Logging | Entry created in compliance DB (includes who, when, what fixed) |

| Feedback Form | Technician rates ease-of-adjustment, weather impact, bolt wear, etc. |

| NOC Alert Clearance | Central system closes incident and recalculates SLA health score |

Technician Experience Improvements from RAM360

| Area | Traditional Workflow | RAM360 Workflow |

|---|---|---|

| Diagnosis | Post-visit visual inspection | Pre-visit digital diagnostics |

| Tools | Manual compass, inclinometer | Live mobile visual interface |

| Confirmation | Subjective validation | Real-time telemetry confirmation |

| Documentation | Handwritten or manual upload | Automated digital logging |

Field Technician Resolution Workflow with RAM360

Step-by-Step Technical Journey

1. Receive Alert and Diagnostic Data (Pre-Site Visit)

- Technician is alerted via the RAM360 Mobile App or NOC Dashboard.

- Alert includes:

- Tower ID and Panel ID

- Live misalignment telemetry (azimuth, tilt, roll deviation)

- Predicted RF coverage loss

- Weather & historical drift patterns

- Mobile app overlays site-specific correction instructions based on AI analysis.

2. Arrive at Site and Begin Guided Resolution

| Phase | Activity | RAM360 Support |

|---|---|---|

| Identification | Technician scans QR on antenna module | Pulls exact profile and last readings |

| Adjustment | Technician uses tools (digital inclinometer, torque wrench) to realign panel | Mobile device shows live deviation with tolerances |

| Verification | Lockdown completed, sensor syncs with cloud | Confirmation that final values are within SLA-specified thresholds |

3. Automated Post-Resolution Verification

- RAM360 sensor module reports new telemetry data to the cloud.

- Dashboard automatically:

- Logs technician name and timestamp

- Updates site status to “Operational”

- Closes maintenance ticket

- Technician receives confirmation and optionally adds comments or uploads photos.

RAM360-IoT Center: Distributed Edge Management and Orchestration Framework

The AT-IoT Center is a scalable, hybrid IoT architecture designed to enable edge-based intelligence, real-time device management, and secure cloud integration for modern industrial and enterprise environments. By leveraging lightweight edge agents, cloud orchestration, and API interoperability, AT-IoT creates a robust ecosystem for deploying, updating, and managing geographically distributed IoT devices.

1. Device and Edge Compute Deployment

The architecture begins with the physical deployment of devices and edge compute units such as:

- Embedded PCs

- Gateways

- Connected sensors and actuators

Each remote location includes edge compute resources capable of pre-processing sensor data and enforcing local logic.

3. AT-IoT Device Registration

Once deployed, devices and compute resources are registered with the central AT-IoT Center, enabling:

- Inventory management

- Logical grouping (by function, region, site)

- Identity and security credential provisioning

5. Real-Time Monitoring and Edge Management

The AT-IoT Center continuously monitors device:

- Health

- Status

- Connectivity

- Performance metrics

This enables remote troubleshooting and event-driven automation without requiring human intervention at the edge.

7. API-Level Integration with Third-Party Tools

AT-IoT exposes RESTful and event-driven APIs, allowing integration with:

- CMMS platforms

- AI/ML engines

- Visualization dashboards (e.g., Grafana, Kibana)

- Network management software

This modularity enables custom workflows and vendor-agnostic orchestration pipelines.

2. Liota Agent Integration

A lightweight agent (e.g., Liota – Little IoT Agent) is deployed to all edge compute devices. This agent is responsible for:

- Registering devices with the AT-IoT Center

- Handling secure telemetry transmission

- Executing edge analytics and rule enforcement

- Providing an abstraction layer for device-agnostic orchestration

4. Bi-directional Data Flows

Data flows seamlessly between:

- Edge devices → AT-IoT Center

- AT-IoT Center → Cloud/Data Centers (Public or Hybrid)

This flow supports both telemetry uplink (sensor data, health status) and downlink commands (config updates, actions).

6. OTA Updates and Patch Management

Security patches or firmware updates are managed centrally. When updates are required:

- The AT-IoT Center packages and signs the patch

- The update is securely deployed to affected edge devices

- Version control and rollback are supported

This ensures continuous compliance with security policies and reduces vulnerabilities across distributed assets.

8. Remote Reconfiguration and Policy Enforcement

From the AT-IoT Center, administrators can:

- Push new configurations

- Adjust data collection rates

- Update rule sets or campaign logic

- Trigger device actions based on analytics feedback

These changes are propagated via the edge agent layer and applied in real time or scheduled windows, ensuring operational flexibility.

AT-IoT Hybrid and Public Cloud Deployment

The architecture supports both hybrid (on-prem + cloud) and fully cloud-native models, allowing:

- Elastic scaling

- Geo-redundancy

- Data residency compliance

Data centers can be vendor-specific or cloud-agnostic (e.g., AWS, Azure, or private OpenStack deployments).

Use Case Scenarios

| Industry | Example Use Case |

|---|---|

| Smart Cities | Traffic sensor orchestration & live congestion analytics |

| Manufacturing | Machine health tracking + predictive maintenance |

| Energy | Grid edge monitoring, transformer telemetry, and auto-patching |

| Retail | Connected POS device updates and campaign synchronization |

Summary

The AT-IoT Center empowers enterprises to orchestrate, monitor, and update thousands of edge-connected devices with real-time insight, secure data flow, and open extensibility. It provides a foundational framework for next-gen IoT deployments that demand autonomous edge intelligence and cloud-managed control planes.

Problem Statement: Cellular Network Antenna Misalignment Detection and Prevention Core Issue: Cellular antennas frequently suffer physical misalignment due to seasonal weather exposure, strong winds, and harsh environmental conditions, resulting in coverage gaps, degraded Quality of Service (QoS), and reduced network performance for voice and data services.

Business Impact: Antenna misalignment creates unplanned service disruptions that violate SLA commitments, requiring reactive site visits and emergency repairs that increase operational costs and customer dissatisfaction.

Solution Need: Telcos require real-time antenna monitoring capabilities (such as RAM360 sensor technology) that provide proactive detection of antenna panel displacement, enabling predictive maintenance scheduling and allowing field crews to arrive with precise repair insights, thereby maintaining network performance standards and reducing Mean Time to Repair (MTTR).

This problem statement captures the reactive nature of current antenna maintenance, the business consequences of misalignment, and positions real-time monitoring as a strategic solution for proactive network management.

RAM360 is an Edge-AI–powered, real-time antenna alignment and network-integrity monitoring platform engineered for carrier-grade deployment. Using a multi-sensor cluster with GPS/GLONASS assistance, the system continuously measures azimuth, tilt, roll, elevation, and vibration with sub-0.1° accuracy, enabling precise detection of alignment drift, structural movement, and service-impacting anomalies long before they manifest in degraded network KPIs. An always-on telemetry pipeline communicates through NB-IoT/LTE CAT-M1, transmitting alignment vectors, vibration signatures, battery metrics, environmental data, and anomaly alerts to the cloud.

A core differentiator of RAM360 is its Edge-AI intelligence, which executes on-device anomaly detection to identify micro-tilt deviations, wind- or vibration-induced drift, mechanical looseness, load imbalance, and early signs of coverage degradation. Its field nodes are power-harvested, fix-and-forget units designed for multi-year operation, supporting remote calibration, configurable thresholds, encrypted data logging, and FOTA updates. At the cloud layer, RAM360 performs baseline learning, drift prediction, RCA insight extraction, and prescriptive maintenance recommendations, enabling network teams to drastically reduce truck rolls, accelerate root-cause identification, and maintain consistent RF coverage quality across large tower fleets.

The RAM360 Proof of Concept validates this architecture end-to-end, demonstrating real-time antenna health visibility without the need for tower climbs, manual compass checks, or vendor-specific RF diagnostic tools. The POC confirms robust integration of IMU, tilt, compass, vibration sensors, edge-controller logic, real-time telemetry, and cloud-visualization dashboards all performing reliably under field-equivalent loading and environmental conditions. The collected structured data supports advanced AI/ML functions such as predictive drift modeling, calibration-anomaly detection, and automated maintenance workflows, establishing RAM360 as an AI-ready platform for next-generation tower intelligence.

The experiments further highlight the platform’s ability to eliminate long-standing RF alignment challenges by providing continuous monitoring, instant multi-vector alerts, vendor-agnostic integration, and a unified single-pane visibility layer. RF planning and optimization teams benefit from live insights into coverage leakage, sector drift, wind-induced orientation errors, vibration-triggered outage patterns, and automated neighbor-cell adjustment cues. Designed for retrofit and greenfield deployments, RAM360 demonstrates clear scalability across geographies, antenna types, and tower architectures confirming its ability to transform antenna maintenance, troubleshooting, and optimization into a fully automated, predictive, zero-touch operational workflow.

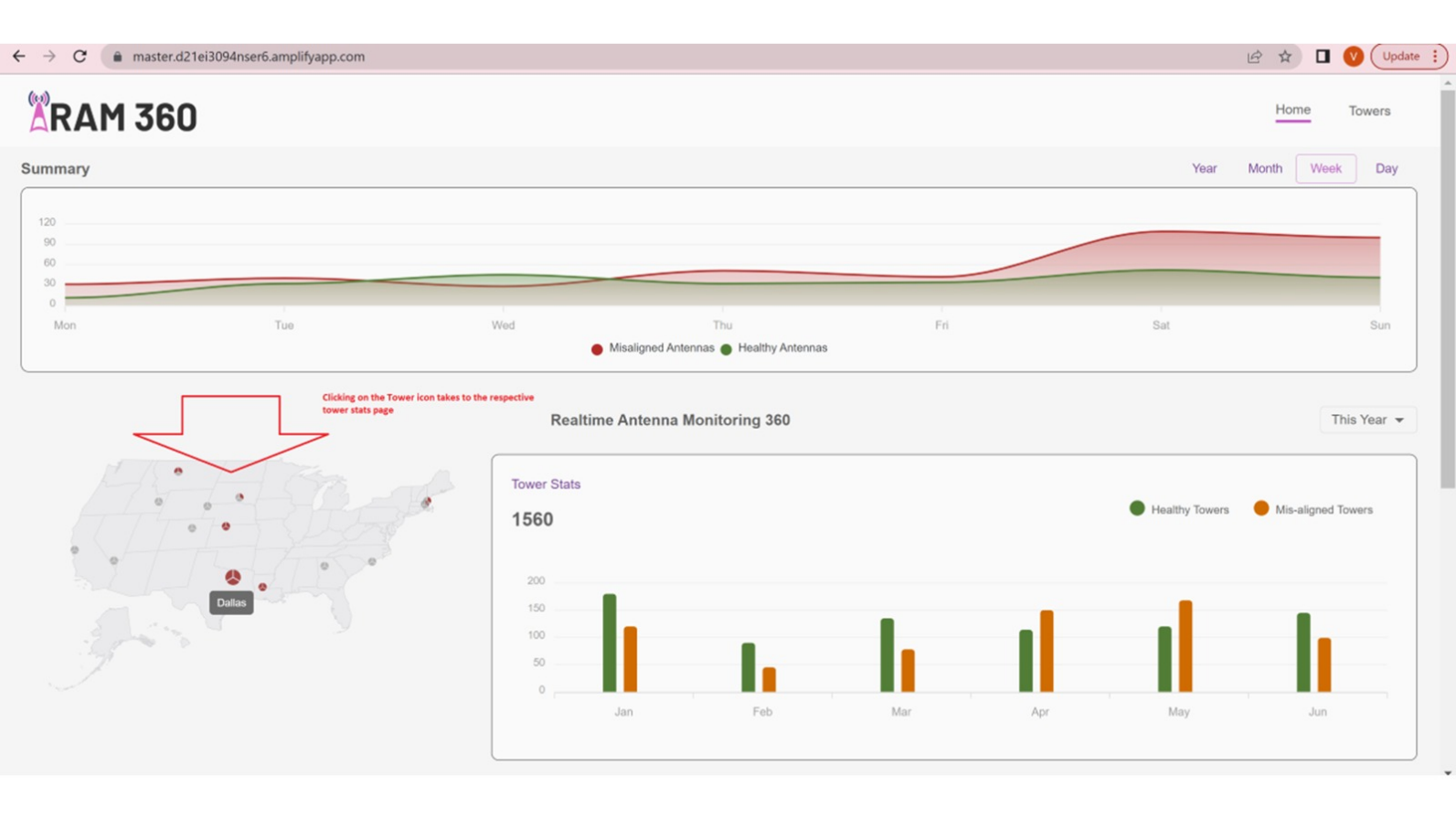

The snapshot illustrates the RAM360 cloud monitoring console, providing a unified, nationwide view of antenna health and alignment performance across the operator’s tower network. The dashboard integrates near-real-time telemetry, geospatial intelligence, and historical KPI analytics to support engineering, NOC, and RF optimization teams.

At the top, the weekly performance summary graph displays trends of misaligned antennas vs. healthy antennas, allowing engineers to quickly see drift patterns, error spikes, or region-specific anomalies developing over time. This time-series overlay offers early warning indicators for coverage leakage, azimuth drift, tilt deviation, or mechanical instability.

The interactive U.S. map view enables drill-down into site-specific metrics each tower icon represents a unique monitored location. Selecting a tower (e.g., “Dallas” in the snapshot) redirects users to that tower’s detailed alignment, vibration, and sensor-health telemetry page. This geospatial visualization allows rapid fault localization and identification of alignment clusters affected by storms, climatic events, or structural degradation.

The bottom section provides Tower Stats, a month-by-month aggregation of healthy vs. misaligned towers, enabling clarity on long-term network behavior, optimization cycles, and maintenance effectiveness. This view provides RF planners and field operations with actionable insights into seasonal drift patterns, power-harvesting variability, or region-specific degradation trends.

Overall, the dashboard snapshot demonstrates RAM360’s ability to merge sensor-driven alignment intelligence, fleet-scale visualization, and KPI analytics, delivering a powerful operational tool that enhances coverage quality, minimizes truck-rolls, and modernizes network maintenance into a predictive, data-driven workflow.

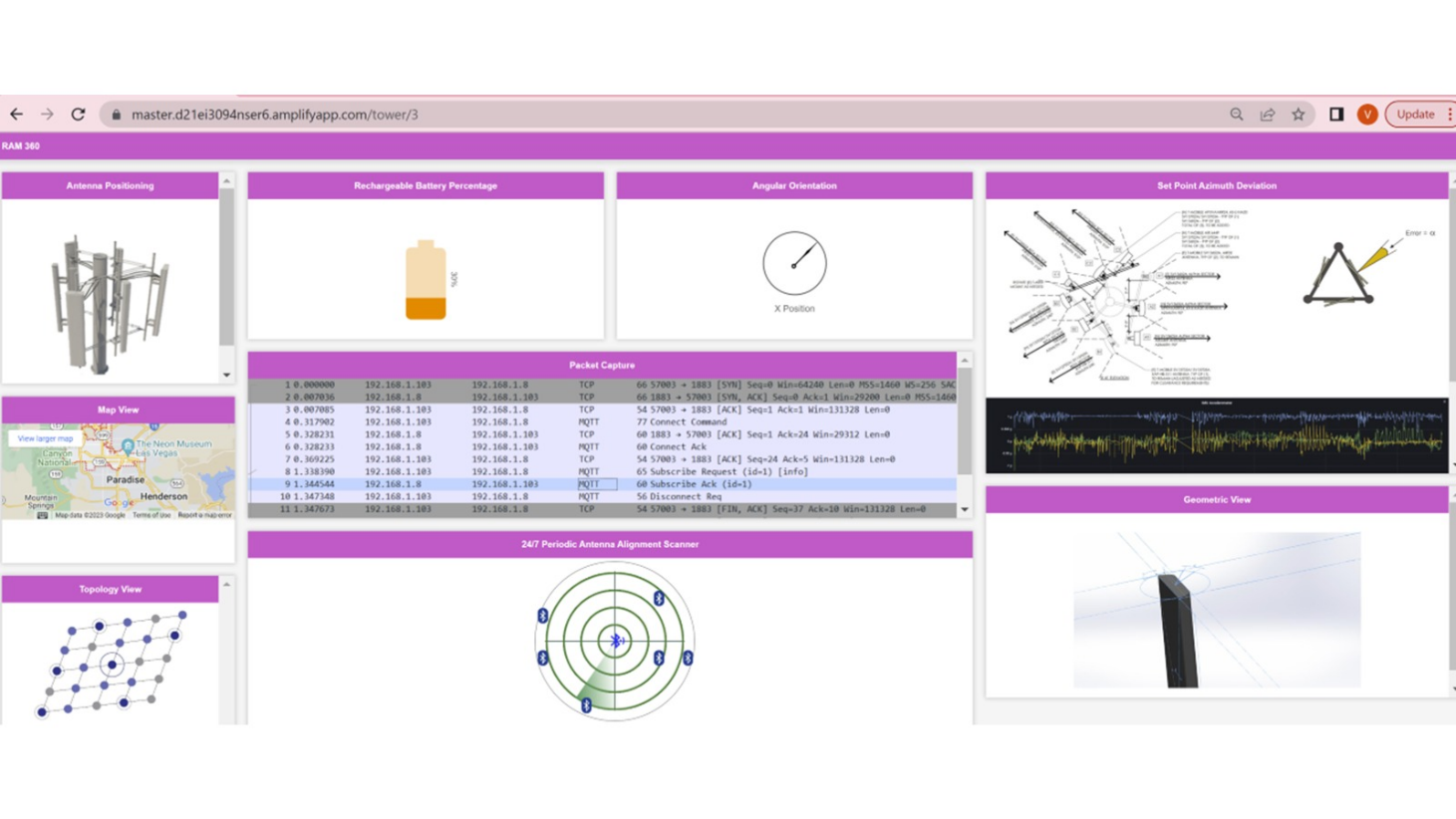

Below snapshot illustrates the fully operational RAM360 real-time antenna analytics and alignment-intelligence dashboard, integrating multiple sensing and telemetry pipelines into a unified engineering view. The platform fuses data from antenna positioning, battery health, angular orientation sensors, and azimuth-deviation detectors, presenting a synchronized visualization of RF, mechanical, and environmental variables.

A live packet-capture analyzer provides deep network-layer visibility including TCP and MQTT transactions allowing field engineers to correlate antenna alignment adjustments with control-plane acknowledgements, configuration pushes, and telemetry backhaul behavior. The 24/7 periodic antenna alignment scanner reveals drift patterns in polar format, highlighting long-term mechanical instability, wind-induced oscillation, or structural fatigue. The geometric projection module simulates the antenna’s expected vs. actual pose, enabling baseline deviation scoring and automated error-vector estimation.

Additionally, the topology map presents network adjacency and sector relationships, supporting load-balancing and tilt-optimization studies across neighboring cells. Together, this integrated multi-panel view demonstrates RAM360’s ability to act as a high-fidelity digital twin of the antenna environment, providing continuous telemetry fusion, anomaly detection, predictive insights, and engineering-grade diagnostics for real-world field deployments.

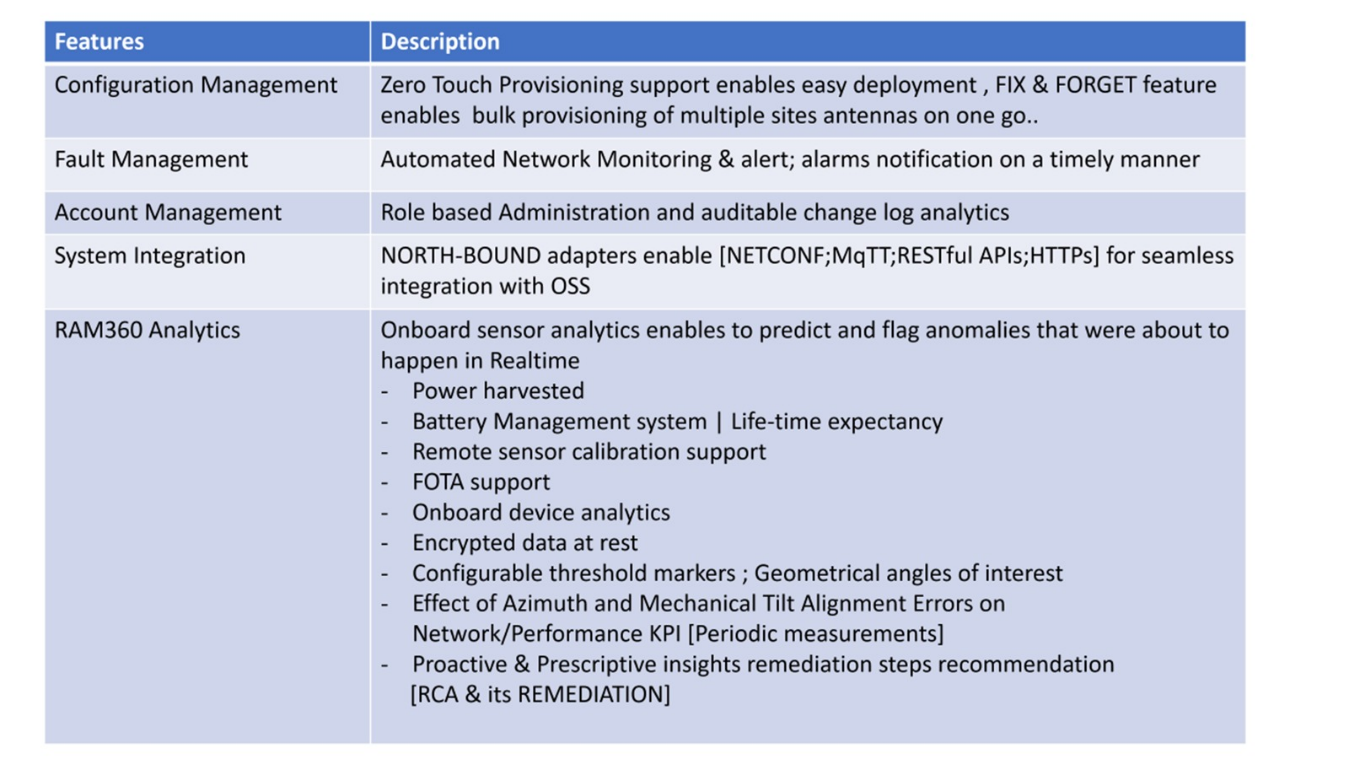

Technical Summary of RAM360 Feature Suite

RAM360 provides a full-stack autonomous RAN-monitoring and optimization platform combining zero-touch provisioning, real-time analytics, northbound OSS integration, and intelligent anomaly prediction. Its Configuration Management engine supports bulk, multi-site antenna deployment through zero-touch provisioning and FIX-&-FORGET workflows, dramatically reducing manual field interventions. Fault Management delivers automated network monitoring with timely alarm notifications, enabling early detection of performance degradations. Account Management is implemented through a secure, role-based administrative framework with complete audit-trail visibility for change-log analytics.

For OSS interoperability, RAM360 offers standards-aligned northbound adapters—including NETCONF, MQTT, RESTful APIs, and HTTPS—ensuring seamless integration across heterogeneous vendor ecosystems. The RAM360 Analytics module forms the intelligence core of the platform, using onboard sensor analytics to continuously identify—and often preempt—anomalies through real-time force, tilt, azimuth, and environmental telemetry. Key capabilities include power-harvesting monitoring, battery-life prediction, remote sensor calibration, and FOTA for field-upgradable firmware. Additional analytic functions cover device-level health scoring, encrypted-at-rest data protection, configurable geometrical threshold markers, and the impact analysis of azimuth/mechanical-tilt alignment errors on overall network KPIs.

RAM360 also performs periodic KPI measurement and learning-based baseline drift detection, enabling proactive and prescriptive optimization workflows. This includes automated root-cause analysis (RCA) with remediation recommendations, allowing operators to intervene before performance loss propagates to subscribers. Collectively, these features position RAM360 as a next-generation autonomous service-assurance platform capable of predictive maintenance, optimized RAN performance, and reliable, scalable field deployment.

BLE-Mesh–Enabled Remote Antenna Alignment Monitoring

BLE Mesh–governed Remote Antenna Alignment Monitoring introduces a highly scalable, low-power, multi-hop sensor network designed to continuously track critical antenna orientation parameters across large tower clusters without dependency on cellular signaling paths. In cellular networks, antenna tilt and transmit power remain two of the most influential parameters affecting coverage footprint, interference control, capacity optimization, and user experience—particularly in interference-limited 4G and 5G systems. Antenna height and tilt (mechanical + electrical) determine how radiated energy propagates across the service area: increasing height reduces path loss, while improper tilt leads to overshooting, coverage holes, excessive handovers, or inter-cell interference. Traditionally, tuning these parameters required repetitive drive tests, tower climbs, and manual audits, resulting in high operational expenditure, safety exposure, and delayed correction cycles. The BLE Mesh–enabled IoT alignment sensors eliminate these inefficiencies by providing continuous, autonomous, and high-precision monitoring of azimuth, tilt, roll, plumb, horizontal/vertical displacement, AGL/MSL height, and geolocation across every antenna in the network. Each sensor operates as a battery-powered node participating in a self-healing mesh topology, enabling long-range, multi-hop communication without the need for IP provisioning, Ethernet, or on-site controllers. The system achieves sub-degree precision (<0.3° RMS azimuth accuracy, ±0.1° tilt/roll), detecting micro-deviations caused by wind, structural fatigue, thermal expansion, ice loading, seismic disturbances, or accidental mechanical impact. Data is relayed through the BLE Mesh backbone to a local gateway, forwarded securely to the cloud, and stored for long-term compliance and advanced analytics.

Operators can configure alarm thresholds, compare real-time values against golden-baseline alignment profiles, generate automated PDF/CSV/Google Earth closeout packages, and integrate telemetry into OSS/NMS environments using REST APIs or MQTT pipelines. This continuous monitoring framework reduces truck rolls, minimizes tower climbs, enhances field crew safety, and ensures that even small alignment drifts affecting QoS are detected and resolved before they impact the network.

Designed for macro/micro cell sites, DAS networks, utilities, transportation, aerospace, and defense systems, the BLE Mesh–based architecture provides a future-proof, cost-efficient method for asset alignment assurance across geographically distributed infrastructure. By combining low-power mesh communication with real-time sensor intelligence, the solution transforms antenna alignment management from a reactive, manual, drive-test–dependent process into a unified, predictive, zero-touch operational model.

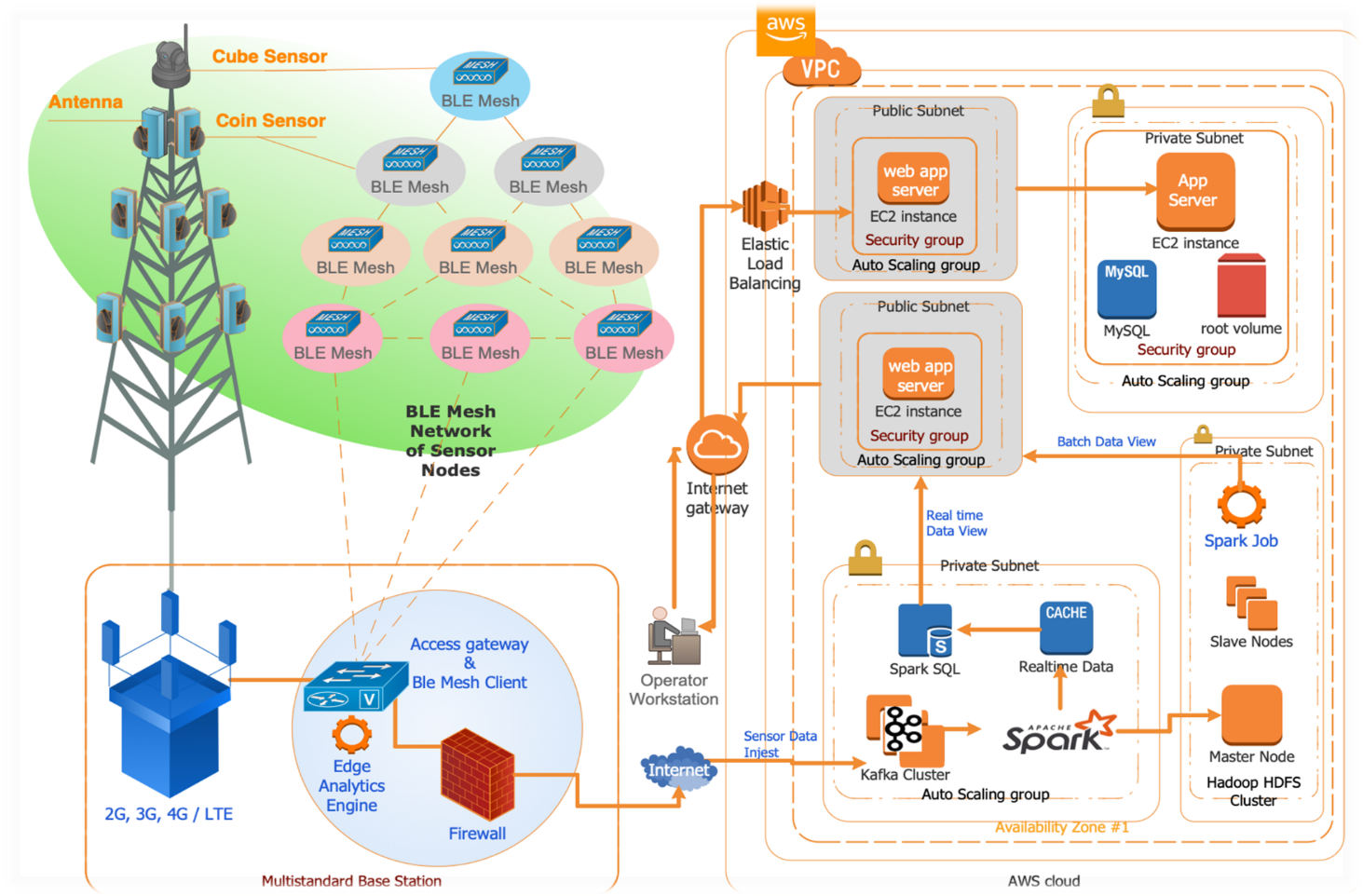

The BLE Mesh–governed antenna alignment monitoring architecture enables large-scale, battery-powered sensor deployments across telecom towers and distributed infrastructure. Cube and Coin BLE sensors installed on RF panels, DAS nodes, and small-cell antennas communicate using a self-healing BLE Mesh network, ensuring resilient multi-hop data propagation even in RF-dense environments.

The mesh network aggregates sensor readings—azimuth, tilt, roll, vibration, GPS, environmental metrics—and forwards them to the multistandard base station, which functions as the Access Gateway + BLE Mesh Client. At this edge layer, an Edge Analytics Engine performs real-time preprocessing, anomaly detection, and event prioritization before securely forwarding telemetry over 2G/3G/4G/LTE uplinks.

Sensor data is ingested into the cloud using an Internet Gateway → Load Balancer → Web App Server cluster running in an AWS VPC. A scalable backend comprising Spark Streaming, Spark SQL, Kafka, and an HDFS-based big-data pipeline provides real-time and batch processing capabilities. Processed insights feed the application server and MySQL database, supporting dashboards, alerts, device lifecycle management, and long-term analytics.

Operators access the system through web interfaces or workstations, enabling tower-level visibility, bulk fleet management, historical alignment replay, predictive maintenance, and automated report generation. This integrated architecture ensures continuous alignment monitoring, reduced truck rolls, enhanced RF performance, and operational cost savings for telecom operators.